BIO – STP

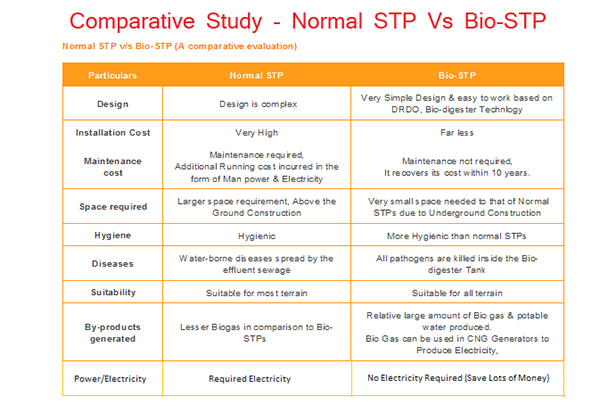

All organic waste disposal in India is a burning problem. The problem has further aggravated in rural places in India & responsible for spreading of Water Born Diseases like Typhoid, Cholera, Shigellosis, Amoebic Dysenteries and Diarrhea etc. With help of this BIO-STP Technology we can overcome with all these problems and make our environment better to live.

Technology Behind Bio-Sewage Treatment Plant

This technology is suitable for any area/ application in India. The process under this technology culminates in to treated effluent which is free from Pathogens and is also environmentally acceptable.

Bio- STP (sewage Treatment Plant) is designed with the following components:-

- BAR SCREEN CHAMBER

- BIO DIGESTER SYSTEM

- REED-BED SYSTEM

- TREATED WATER STORAGE TANK

Bar Screen Chamber

A bar screen is a mechanical filter used to remove large objects, such as rags and plastics, from wastewater. It is

part of the primary filtration flow and typically is the first, or preliminary, level of filtration, being installed at the influent

to a wastewater treatment plant.

The screening system washes and dewaters the debris before discharging it into a garbage can. The screened

wastewater then flows to an aerated grit chamber that facilitates the sedimentation of heavier inorganic materials,

such as sand and grit, by reducing the velocity of the wastewater.

Bio Digester Tank

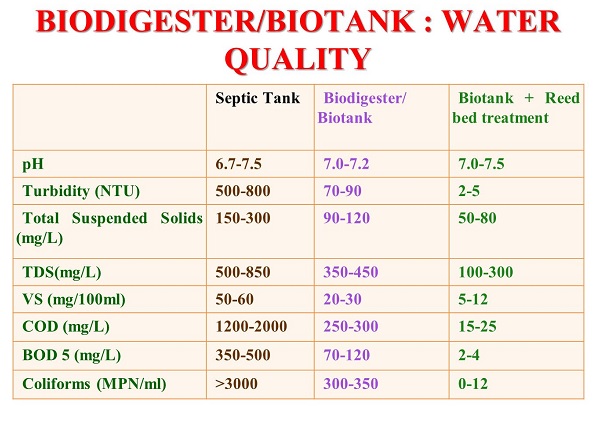

Technology is developed and approved by DRDO-Ministry of Defence an innovative technology for disposal of Organic waste in an eco-friendly manner in bio digesters. These bio digesters can function at any atmospheric temp between -55°C to 60°C. The bacterial consortium degrades night soil at temp as low as -55°C and produces colourless, odourless and inflammable biogas containing 50%-70% methane.

The main constituents of bio digesters are AMI which is filled into the bio digester in a capacity of 40% to the volume of bio digesters tank. Black & Grey water from Housing Multiplexes, Villages, and Public Places are connected to the bio digester. Night soil degradation occurs through microbial reaction which converts it into biogas & Clean Water.

The smell of night soil, the disease causing organisms in the night soil and the solid matter are eliminated totally. On a dry weight basis 90% of the solid waste is reduced. The gaseous effluent (Biogas) is continuously let off to the atmosphere/Biogas can be used for various energy incentive activities like cooking, water and room heating. Liquid effluent can be drained to any surface or soak pit without any environmental hazards.

REED – BED System

Reed Bed has become the principal wastewater treatment method around the world. Reed beds (vertical flow subsurface constructed wetlands) are the most significant advance in water and waste treatment since the activated waste process was first used over a century ago. Reed bed technology designs and constructs highly effective and simple to operate systems for treating a wide range of contaminant chemicals including ammonia, BOD, COD, suspended solids, organic chemicals, chlorinated organic chemicals, industrial solvents, and hydrocarbons.

Reed beds rely on biological processing of contaminants to treat water to a quality suitable for environmental disposal or reuse. But unlike activated waste, reed beds consume no energy, require no chemicals, have no moving parts, and are carbon neutral. Reed beds have been operating across Europe and the US for over 20 years to manage and treat domestic wastewater, water treatment

waste, leachate and contaminated groundwater, and mining and industrial process water. These systems are still in operation today and continue to function with very little maintenance.

We design and install Reed beds to treat domestic wastewater, domestic waste water, industrial wastes and contaminated wastes and mine waters. Our reed beds transform and remove a range of different contaminants from these wastes, including organic loads (BOD), petrochemicals & solvents, suspended solids & sediments, metals and nutrients.